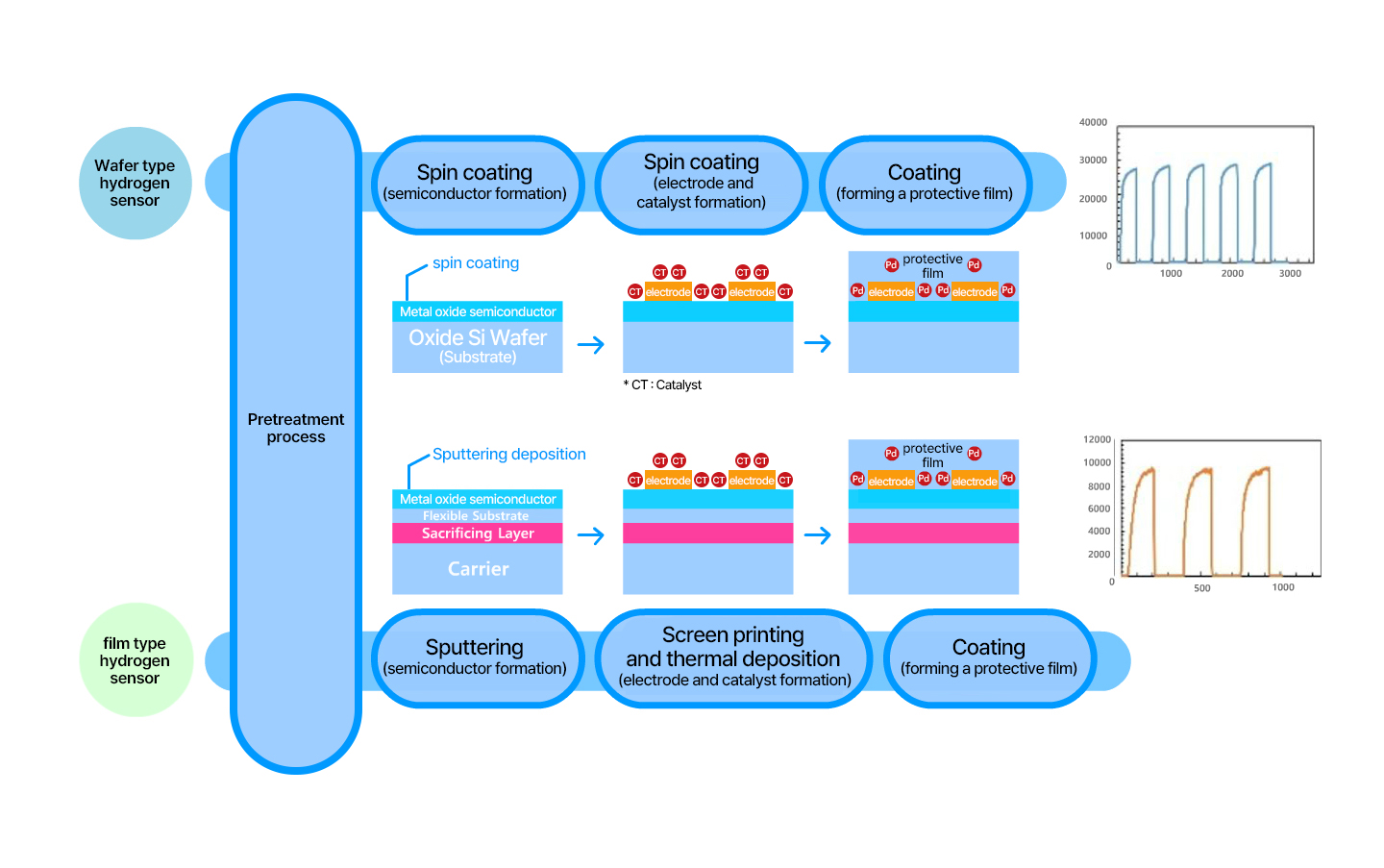

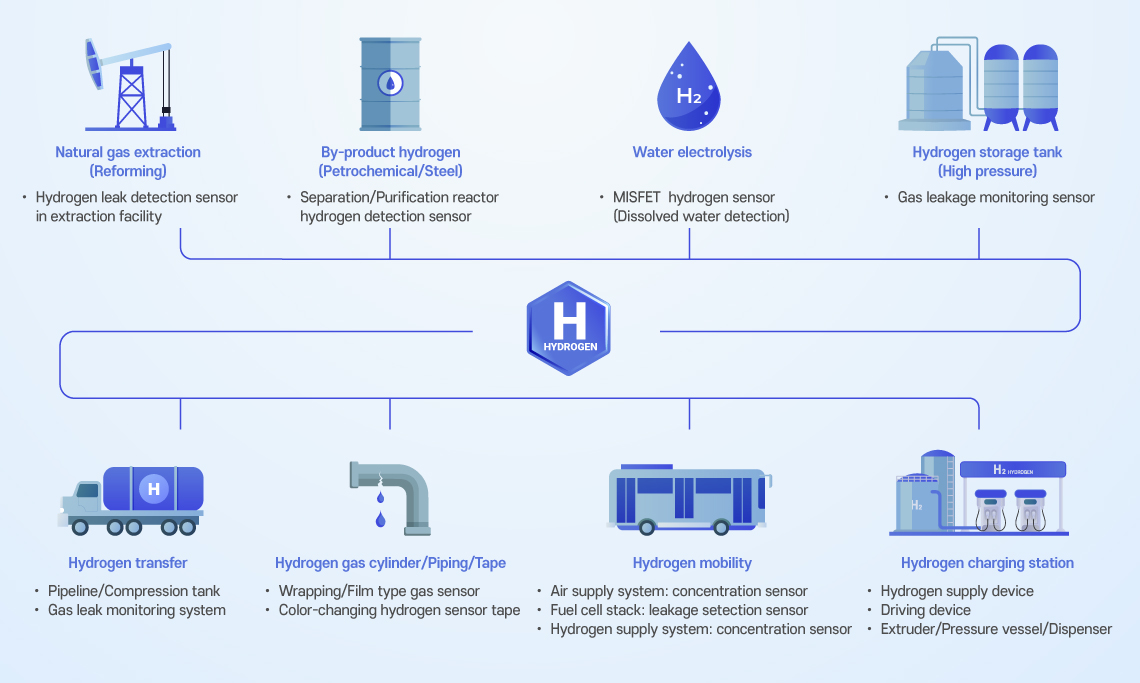

Taesung Nano FAB is developing various harmful gas sensor elements and materials based on wafers and thin films, and plans to release products such as hydrogen film sensors, ammonia film sensors, and large-area film sensors through semiconductor manufacturing nanoprocesses, and is securing MEMS-type packaging technology.

SEMICONDUCTOR

Sensor Development Center

Sensor Development Center.

Preparing to launch a biosensor for vitamin D diagnostic technology using quantum dot technology, we are developing an optical sensor that can detect volatile organic compounds (VOCs) and carbon dioxide using extreme ultraviolet (PID) and non-dispersive infrared (NDIR).

While designing various types of hydrogen detection film sensors for detecting hydrogen leakage in components/products/equipment/facilities required for hydrogen production/storage/transportation, we are developing wafer-based hydrogen detection film sensors, printed hydrogen detection film sensors, hydrogen detection electrical film sensors, hydrogen detection color change tape sensors, and hybrid hydrogen detection film sensors. We are preparing to launch them in the domestic and international markets.

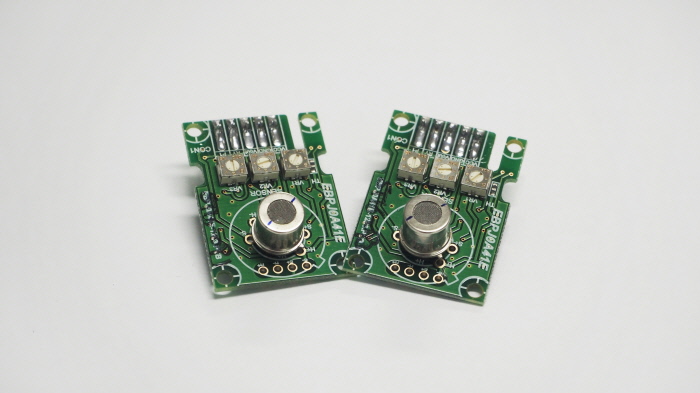

Odor sensors are essential elements that can replace the human nose.

| Display value | Type of odor, intensity, causing substance, causing substance concentration |

| Measuring method | Atmospheric diffusion method |

| Sensor type | PID type sensor, electro-chemical sensor, semiconductor type sensor |

| Measuring gas | VOC series, sulfur series, amine series, fatty acid series, aldehyde series |

| Resolution | ppb |

| Operating environment | -20~60℃, 5~95%RH (non-condensing) |

| Case | Stainless steel, waterproof and dustproof |

| Communication | Wired (TCP / IP, RS232, RS485) Wireless (Zigbee, RF, WCDMA) |

| Other devices | Wind direction, wind velocity, temperature and humidity, atmospheric pressure meter |

| Other devices | Real-time wireless odor monitoring (Zigbee, RF, WCDMA) |

| Characteristics | Real-time monitoring using 24 kinds of sensors Simultaneous monitoring of VOC, hydrogen sulfide, ammonia, fatty acid series, aldehyde series, and temperature and humidity values Type of smell and intensity display Data communication method (wired, wireless, etc.) selectable Weather measurements such as wind direction, wind speed, temperature and humidity, and atmospheric pressure Corrosion prevention using stainless steel Waterproof and dustproof Ease of maintenance |

| Number (No.) | reactant | detection concentration(PPM) |

|---|---|---|

| 1 | VOC | 0~200 |

| 2 | VOC | 0~20 |

| 3 | Carbon dioxide | 0~1% |

| 4 | Methane | 0~5% |

| 5 | Hydrogen sulfide | 0~30 |

| 6 | Ammonia | 0~100 |

| 7 | Ozone | 0~1 |

| 8 | Nitrogen dioxide | 0~50 |

| 9 | Ammonia | 0~100 |

| 10 | Hydrogen sulfide | 0~30 |

| 11 | Sulfur dioxide | 0~20 |

| 12 | 탄화수소 | 0~1000 |

| 13 | Hydrocarbon | 0~3000 |

| 14 | Proton butane | 0~1000 |

| 15 | Hydrogen | 10~1000 |

| 16 | Alcohol | 0~100 |

| 17 | Freon | 0~1000 |

| 18 | Hydrogen | 0~100 |

| 19 | VOC | 0~1000 |

| 20 | Ammonia | 1~50 |

| 21 | Alcohol Ammonia VOC | 1~10 |

| 22 | Trimethylamine hydrogen sulfide | 1~10 |

| 23 | Alcohol organic solvent | 50~5000 |

| 24 | Hydrogen alcohol | 1~10 |