SEMICONDUCTOR

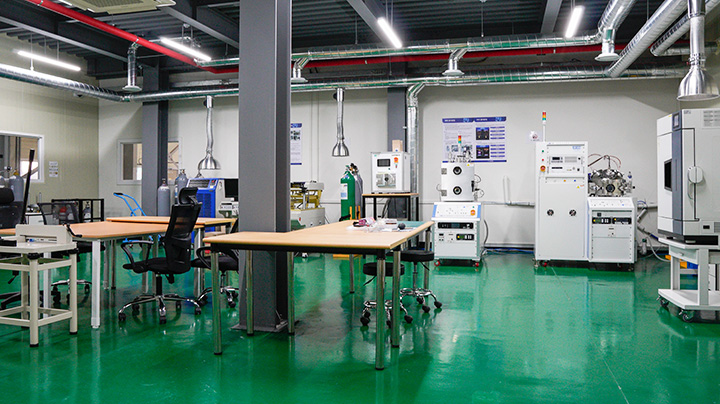

Nano FAB Center

Development of non-memory semiconductor-based sensor technology

We have a sensor platform that can be used in the hydrogen industry, eco-friendly ships, and eco-friendly workplaces, and are pursuing the development of more advanced technologies.

Nano Materials Laboratory

Air Shower Room

Deposition Room

Measurement Room

Photolithography Room

Chemical Laboratory

Sputter

This is equipment that forms a thin layer using thin film deposition technology. This device uses high-energy particles (usually ions) to remove particles from the surface of a solid material and deposit them on another surface, creating a thin film.

Thermal Evaporator

This is a device that heats and evaporates materials, thereby forming a thin film on a substrate or other surface. This is equipment that heats the source material and deposits it on the substrate to form a thin film.

Screen Printer

This is a technology that prints specific patterns or electrodes. By doing this, the design or electrode required for the sensor can be applied precisely. Screen printing is a highly productive and cost-effective method for manufacturing a variety of sensors.

Slot-die Coater

This is equipment used to uniformly coat a thin film onto a special subsurface. It is used in a variety of applications requiring thin film coatings, primarily in industry and research. It can work continuously and maintain the correct coating thickness, supporting an efficient and accurate process.

Probe Station

This is equipment for testing or measuring specific devices or devices such as semiconductors or electronic devices. Basically, a probe station stably positions a small sample or device and makes an electrical connection via a special probe card or needle. This allows you to measure electrical properties such as voltage, current, resistance, and capacity, or investigate optical properties.

Mask Aligner

It is an optical lithography equipment that can obtain fine patterns by placing a photo mask with a circuit drawn on a semiconductor wafer or glass substrate coated with photo resist (PR) and irradiating UV light. Precision alignment is possible and can be applied to precision alignment and patterning of touch screen panels, flat displays, MEMS/Bio-MEMS, LEDs, etc.